myCSUSM

myCSUSMUtility Mark-Out Information

Welcome to the Utility Mark-Out Information Center for Facility Services at Cal State University San Marcos.

Mark Out Policies and Procedures

Why should I delineate?

Marking of underground facilities and proposed excavations is the key to damage prevention in the field. With both parties, the excavator and the locator, marking in harmony will make life simpler for both parties. I.e.: If an excavator does not properly delineate his dig location the locator may not mark the entire area or he may waste his time marking too much area. Or if the locator does not properly mark his facilities the excavator may waste his time calling to get the facility owner back out to re-mark their facilities.

|

Utility |

Color Code |

|---|---|

|

Electric |

Red |

|

Gas-Oil-Steam |

Grey |

|

Communication and Cable TV |

Orange |

|

Water |

Blue |

|

Sewer

|

Green

|

|

Reclaimed Water |

Pink |

|

Proposed Excavation |

White |

Suggested Guidelines for Prospective Excavation Site Delineation and Facility Owner Location Mark out

This guide provides for temporary uniform surface markings of both planned excavations and of substructures in potential conflict of planned excavations. White markings are used for excavation delineation. Substructure markings are of a specific color. Appropriate color and common abbreviations are listed herein.

Note: Temporary markings should be clearly seen, functional, and considerate to surface aesthetics and local community. Also, check to see if any local ordinances apply.

Marking in Paved Areas

Avoid excessive or oversized marking, especially if marking outside the excavation area. Conditions permitting, use spray chalk paints, water based paints or equivalent less permanent type marking. Limit length, height, and interval of marks to those recommended. Letters and numbers should not exceed 3" to 6" in height.

Marking in Non-Paved Areas

When paint is not used, use appropriately colored stakes, lath, pennants or chalk lines. Select marker types that are most compatible to the purpose and marking surface. Adhere to paved area marking suggestions to the extent practical.

Guidelines for Excavation Delineation

- Excavators are reminded that pre-marking (delineation) of excavations.

- Delineate the area to be excavated before calling Facility Services. Delineated areas should be identified in white markings with the requester's company name or logo within the pre-marked zones (see examples).

- Failure to pre-mark when practical may jeopardize your permit, or result in civil penalty.

- "If pre-marking is not practical, the excavator shall contact" ..Facility Services..." to advise the operators that the excavator shall identify the area in another manner sufficient to enable the operator to determine the exact area of the excavation to be field marked."

- "Delineation must not be misleading, duplicative or misinterpreted as traffic or pedestrian control."

Single Point Excavations

Delineate the exact area of excavation through the use of dots or dashes, or continuous solid line. Limit the size of each dash to approximately 6" in length and 1" width with interval spacing not less than approximately 4 feet. Dots of approximately 1" diameter are typically used to define arcs or radii and may be placed at closer intervals in lieu of dashes. Limit width of lines to 1".

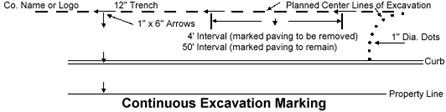

Trenching, Boring, or Other Continuous Type Excavations

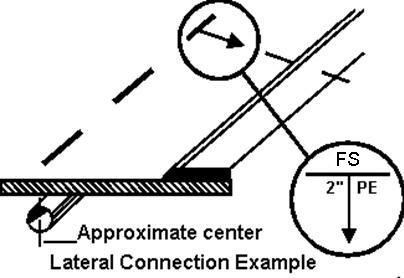

Mark center line of planned excavation with 6" x 1" arrows (approximately 4' apart) to show direction of excavation. For boring or continuous operations where marked paving is not to be removed, mark at critical points with maximum mark separations of approximately 50". Mark lateral excavations with arrows showing excavation direction from center line with marks at curb or property line if crossed. Intermittently indicate excavation width on either side of center line in 3" to 6" high figures. Dots may be used for curves and closer interval marking.

Guidelines for Facility Owner Location Markout

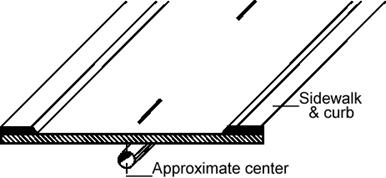

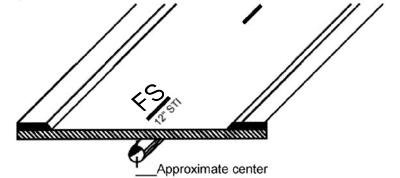

Marks in the appropriate color should be approximately twelve (12) to eighteen (18) inches in length, spaced no more than fifty (50) feet apart. The marks should be placed over the approximate center of the facility.

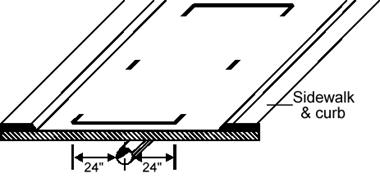

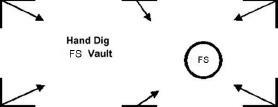

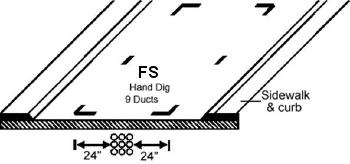

As an alternate, or in addition to, marks can be placed on either side of the facility to define the "Hand Dig Area". The "Hand Dig Area" is defined as the width as the width of the facility itself plus the tolerance zone of twenty-four (24) inches either side of the facility.

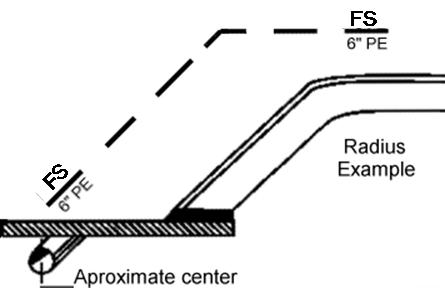

Information as to the size and composition of the facility should be marked at an appropriate frequency, if known. Examples are: the number of ducts in a multi-duct structure, diameter of a pipeline, and whether it is steel, plastic, bare cable, etc. If known, a facility installed in a casing should be identified as such. Examples are: 6" plastic in 12" steel = 6PE/12STL, fiber optic in 4" steel = FO/4STL. Changes in direction and lateral connections should be clearly indicated at the point where the change in directions or connection occurs, with an arrow indicating the path of the facility. A radius should be indicated with marks describing the arc.

Structures, such as vaults, that are physically larger than obvious surface indications, should be marked so as to generally define the parameters of the structure:

Termination points or dead ends should be indicated as such:

If there is "no conflict" and the work area has been pre-marked, no conflict should

be marked along with company designator within the delineated work area* or the excavator

should be notified verbally, or in writing (e.g. fax). If the work area is not delineated,

the excavator should likewise be notified verbally or in writing.

* Caution- Allow adequate space for all facility mark-outs.

No conflict marking indicates that there are no facilities within the scope of the delineation or within the work area as described on the locate ticket.

Example of marking with an implied sixty (60) inch "Hand Dig Area" (12" facility plus 24" to the right and 24" to the left):

Example of marking with "Hand Dig Area" outlined:

Common Marking Identifiers:

- E = Electric

- G = Gas

- SD = Storm Drain

- S = Sewer

- SL = Street Lighting

- TEL = Telephone

- TS = Traffic Signal

- TV = Television

- W = Water/Reclaimed Water

- USA = Underground Service Alert

Common abbreviations and descriptions as used in underground construction:

- ABS = Acrylonitrile-butadiene-styrene

- ACP=Asbestos cement pipe

- CAP=Corrugated aluminum pipe

- CIP=Cast iron pipe

- CMC=Cement mortar coated

- CML=Cement mortar lined

- CSP=Corrugated steel pipe

- CU=Cooper

- DIP=Ductile iron pipe

- DU=Duct

- ELC=Electrolyte lighting conduit

- FC=Fiber conduit

- GIP=Galvanized iron pipe

- GSP=Galvanized steel pipe

- IP=Iron pipe

- MCD=Multiple concrete duct

- MTD=Multiple tile duct

- P=Plastic(conduit or pipe)

- PB=Pull box

- PC=Plastic conduit

- PE=Polyethylene

- PL=Property line

- PVC=Polyvinyl chloride

- R=Radius

- RCB=Reinforced concrete box

- RCP=Reinforced concrete pipe

- SCCP=Steel cylinder concrete pipe

- STL=Steel

- STRUC=Structure

- T=Transmission facility

- TR=Transite(asbestos cement pipe)

- Trans=Transition

- TSC=Traffic signal conduit

- VCP=Vertrified clay pipe